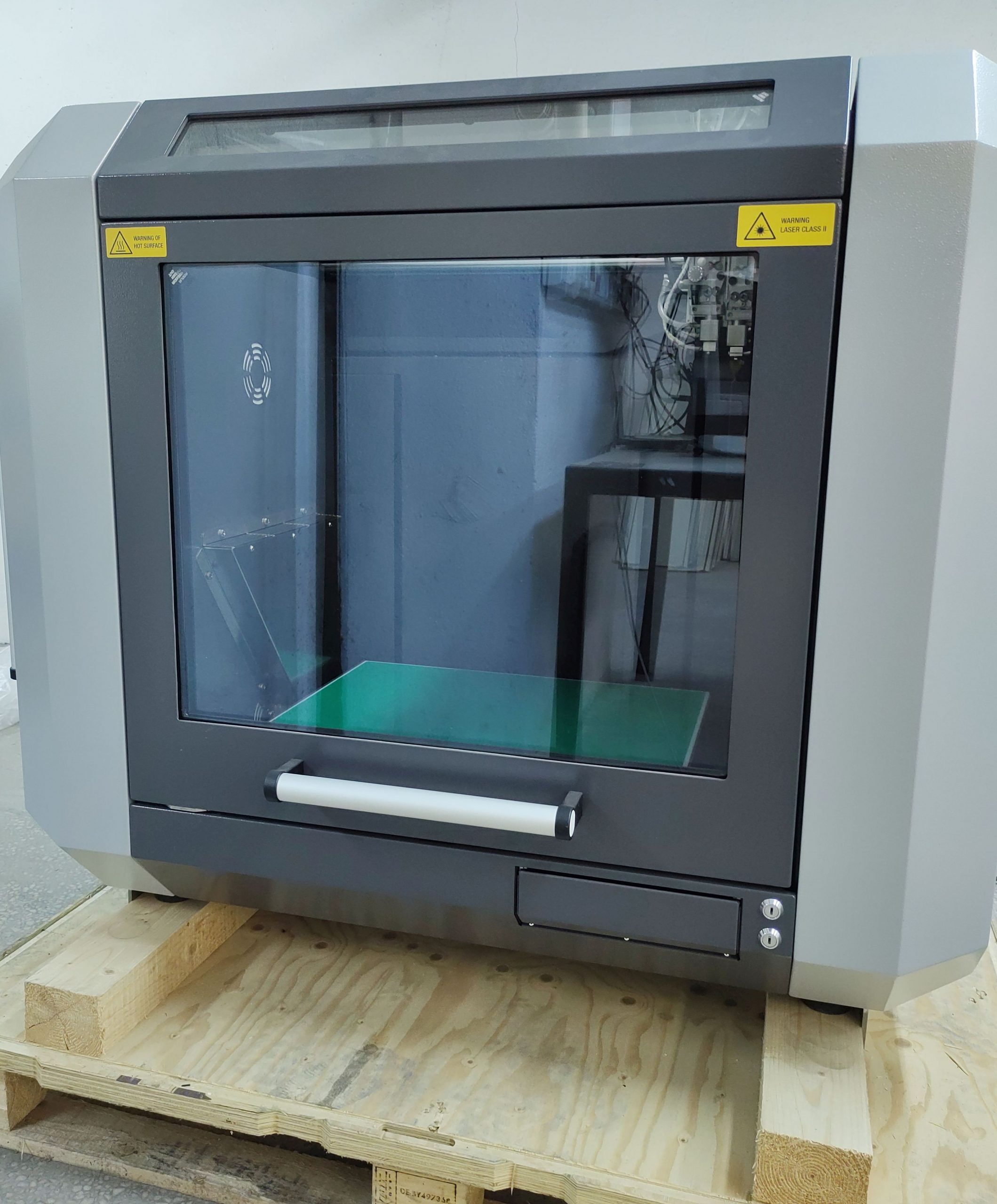

German RepRap x500

German RepRap x500 is an industrial heavy duty 3D printer. It’s robust and heavy stable steel case (180 kgr) allows high precision 3D printing. The printer has a heated build chamber (80°C) with class windows, a high-temperature dual-extruder module with a liquid cooling system that allows high printing temperatures and a large volume of 500 x 400 x 450 mm printing area. It is compatible with any type of 1.75mm filament, it has an auto bed leveling system, which automatically calibrates the build plate before each print, a filament detection system that constantly tracks the material feeding to prevent nozzle clogging and filament jamming allowing unattended continuous 3D printing.

The printer comes with a built-in 7-inch touchscreen, which enables standalone operation but it can also be controlled remotely over the network.

Files can be transferred via USB, Ethernet, or over Wi-Fi.

Remote monitoring via webcam is also possible.

The printer works with the Simplify3D slicer softwar

German RepRap X500 is widely used for the production of durable parts and functional components for industrial applications.

Product Key Features

Build platform (XxYxZ): 500 x 400 x 450 mm

Print speed: 10 – 150 mm/s

Travel speed: 10 – 300 mm/s

Repeat accuracy (X/Y): +/- 0,05 mm

Layer heigh (min.): 0,02 mm

Filament diameter (standard): 1,75 mm

Nozzle: 0,4 Ø mm (opt.: 0,25 / 0,30 / 0,5 / 0,6 / 0,8)

Material: PPLA, ABS, HIPS, PC, DuPont ZYTEL, ASA, CARBON 20, PVA, PET-G TPU, PEI, BVOH, PEKK, and other materials.

Extruder type: DD4 Dual

Extruder temperature (max.): 400°

Print bed technology: heatable

File transfer: Stand-Alone Printing with Touch Display, USB, Ethernet, WLAN optionally

Software: Simplify3D Software

Operating voltage: 230 VAC

Ambient temperature: 15-26°C

Dimensions approx. (WxDxH): 1120 x 850 x 955 mm

Weight approx.: 185 kg

Heated Building Chamber: 80°

Heat Bed (max.): 120°Technology

FFF (Fused Filament Fabrication)